What is CNC machining in San Martin Watch case production?

“`html

In the world of high-quality watch production, precision and craftsmanship are paramount. One pivotal technique employed in the manufacturing process is CNC machining. In this article, we will delve into what CNC machining is, its significance in the production of San Martin watch cases, and why it is the preferred choice among watchmakers. We will also address common questions potential buyers might have regarding the product, emphasizing how this technology enhances the overall quality of timepieces.

What is CNC Machining?

CNC machining stands for Computer Numerical Control machining. It is a manufacturing process that utilizes computer software to control machine tools. This technology allows for the precise cutting, shaping, and finishing of materials to create intricate components. CNC machining has revolutionized various industries, including automotive and aerospace, and has made a significant impact in watchmaking, especially with brands like San Martin.

How Does CNC Machining Work?

The CNC machining process involves several key steps:

- Design Creation: The manufacturing process begins with a detailed design created using CAD (Computer-Aided Design) software. This design outlines every dimension and feature required for the watch case.

- Programming: Once the design is finalized, it is converted into a CNC program. The program consists of coded instructions that tell the machine exactly how to move and operate.

- Material Selection: Various materials can be used in CNC machining, but for San Martin watch cases, high-grade metals such as stainless steel or titanium are commonly selected for their durability and aesthetic appeal.

- Machining Process: The CNC machine, equipped with tools like mills or lathes, follows the programmed instructions to produce the watch case. It removes material from the workpiece with unmatched precision.

- Finishing: After machining, the components undergo finishing treatments to enhance their appearance and durability. This may include polishing, anodizing, or surface coating.

Benefits of CNC Machining for San Martin Watch Cases

The incorporation of CNC machining in the production of San Martin watch cases offers several advantages:

1. Precision and Accuracy

One of the most significant benefits of CNC machining is its ability to deliver unparalleled precision . Watch cases require exact dimensions and specifications to ensure the perfect fit for the movement and other components. CNC machines can achieve tight tolerances that are often impossible with manual machining.

2. Efficiency

CNC machining allows for automation of the production process, which significantly increases efficiency. Once a machine is programmed, it can run for hours without human intervention, producing multiple components in a fraction of the time it would take to manufacture them manually.

3. Versatility

CNC machining is versatile and can work with various materials and complex designs. This flexibility is crucial for watchmakers like San Martin, who aim to produce diverse styles and collections with different materials.

4. Consistency

For any manufacturer, consistency is key, and CNC machining excels in this area. Each piece produced is virtually identical, eliminating variations that can occur in hand-finished products. This level of consistency is vital in the luxury watch market, where brand reputation hinges on quality.

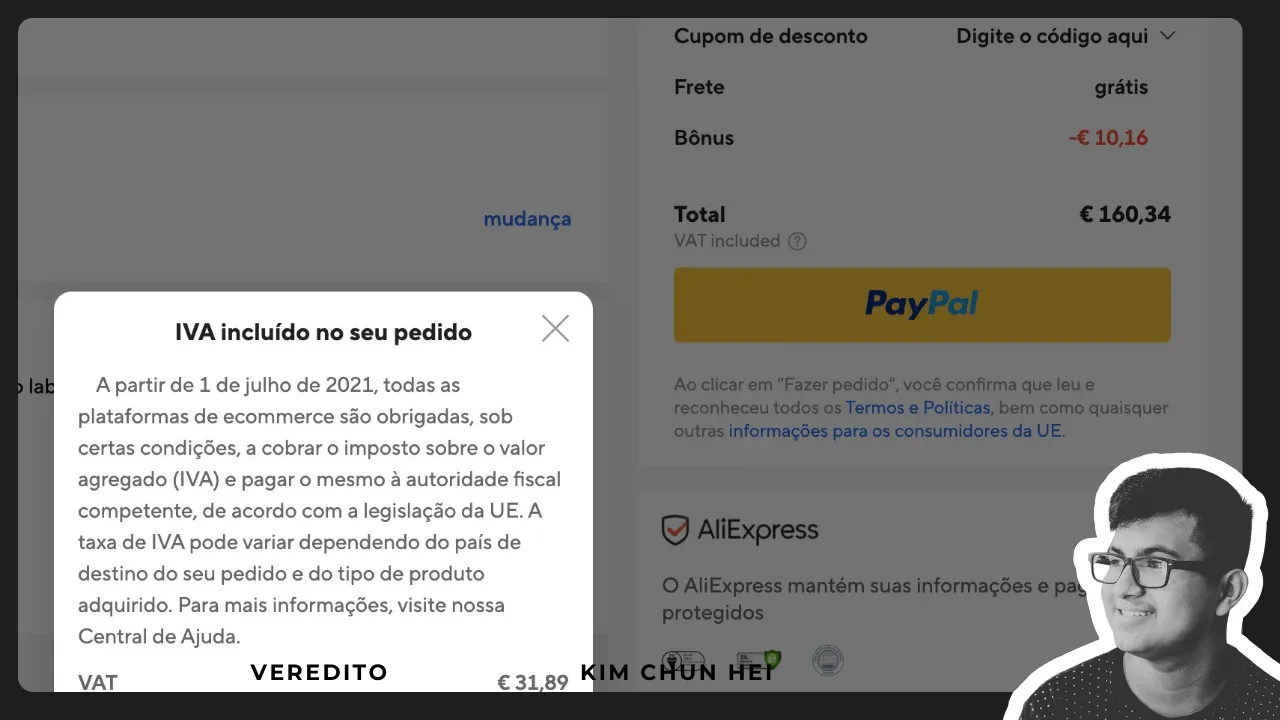

5. Cost-Effectiveness

While the upfront cost of CNC machines may appear high, the reduction in labor costs, increase in production efficiency, and decrease in material waste make CNC machining a cost-effective solution in the long run. For San Martin, this means they can offer their customers high-quality watches at competitive prices.

CNC Machining vs Traditional Watchmaking Techniques

Traditionally, watchmaking involved a high degree of manual labor, which, while skilled, often resulted in inconsistencies and longer production times. Here’s how CNC machining compares to these conventional techniques:

- Speed: CNC machining can dramatically reduce production time compared to traditional methods, allowing for quicker turnaround for new designs.

- Labor: The reliance on manual labor in traditional methods can lead to human error. CNC machines offer a higher degree of reliability and less risk of mistakes in machining.

- Scalability: CNC machining can easily scale production to meet demand, while traditional methods may struggle to keep up with increased orders.

The Role of CNC Machining in the San Martin Brand

San Martin is renowned for its meticulous craftsmanship and commitment to quality. By employing CNC machining, the brand amalgamates modern technology with traditional watchmaking principles. This marriage of precision engineering and artisan design allows San Martin to remain competitive in the luxury watch market.

1. Quality Assurance

Each San Martin watch case is subjected to rigorous quality control, facilitated by the precision of CNC machining. This ensures that every product meets the high standards expected of luxury timepieces.

2. Innovation in Design

With CNC machining, San Martin can experiment with innovative designs that were previously deemed unfeasible. This capability opens up endless opportunities for creativity, enabling the brand to introduce unique and stylish cases that appeal to customers.

3. Sustainability

Modern manufacturing practices have placed a strong emphasis on sustainability. CNC machining minimizes waste during production, making it a more environmentally friendly option compared to traditional methods. San Martin’s commitment to sustainability resonates with conscious consumers.

Common Misconceptions About CNC Machining

Despite its numerous benefits, CNC machining often faces misconceptions. Understanding these can help potential buyers appreciate the value of San Martin watches:

1. It Makes Watches Less Unique

Many believe that CNC machining leads to mass-produced, uniform products. However, it can actually enhance creativity in design, resulting in unique pieces tailored to individual tastes.

2. Higher Prices Mean Better Quality

While high-quality materials and skilled craftsmanship do come at a price, CNC machining enables brands like San Martin to offer exceptional watches at competitive prices without compromising on quality.

3. CNC Machining Is Only for Mass Production

While CNC machining excels in mass production, it also caters to smaller, bespoke runs of watches. San Martin uses this technology not just for volume but to ensure every piece in their collection meets high standards.

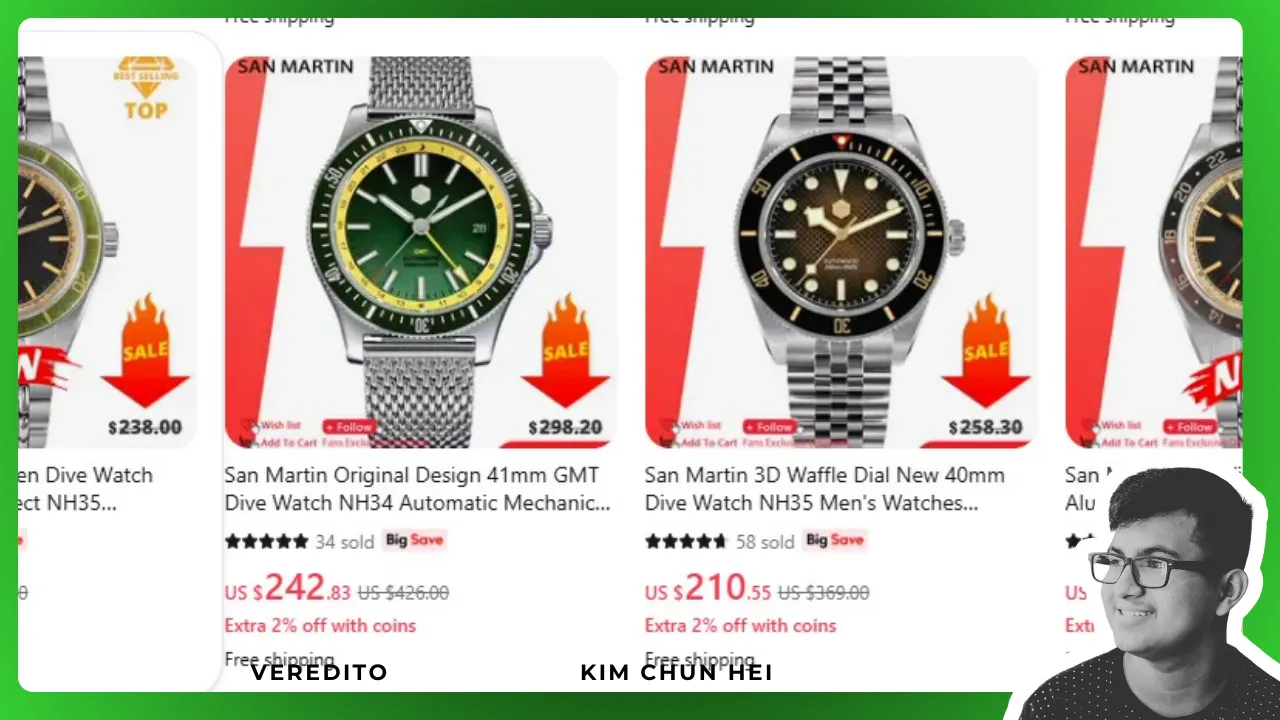

Why Choose San Martin Watches?

When it comes to selecting a watch, the decision goes beyond aesthetics. Here’s why San Martin stands out among other brands:

- Craftsmanship: Every San Martin watch is crafted with precision, ensuring durability and reliability.

- Innovative Design: San Martin integrates CNC technology, allowing for designs that are stylish and functional.

- Value for Money: Offering luxury features at competitive prices makes San Martin an attractive choice for watch enthusiasts.

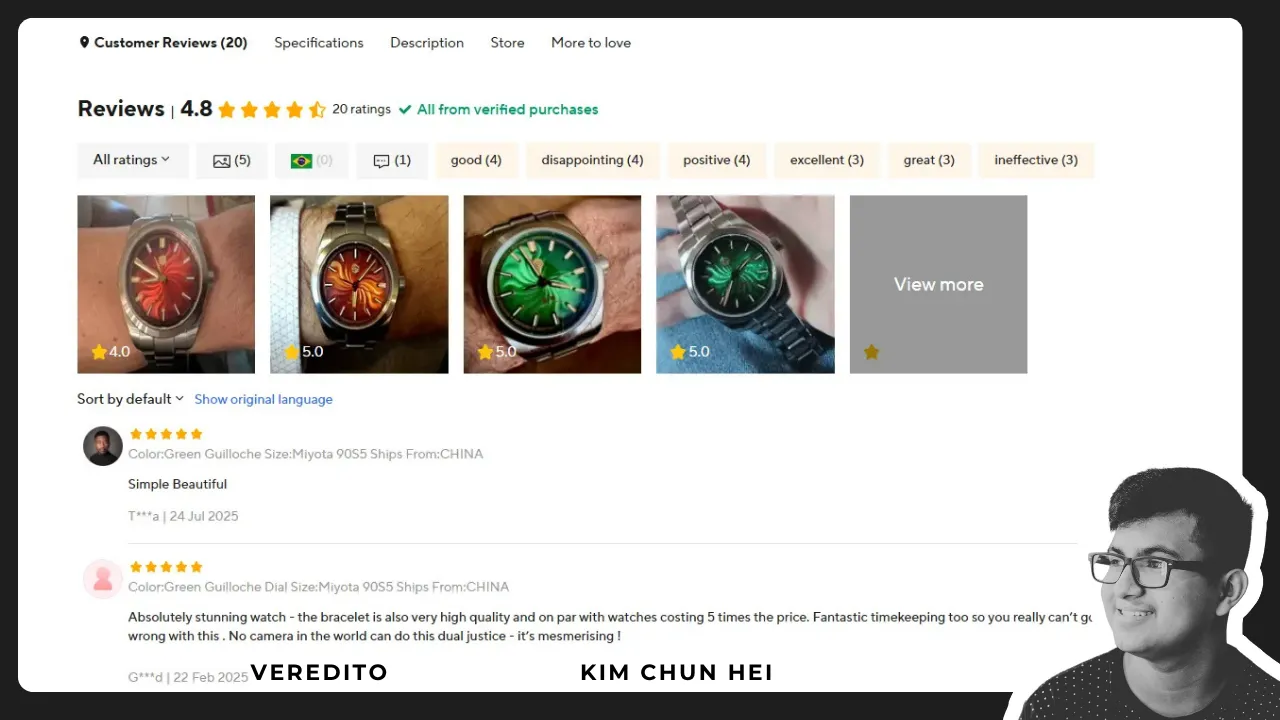

- Customer Satisfaction: The brand is committed to building a loyal customer base through excellent service and quality assurance.

Whether you are a seasoned collector or a newcomer to the world of watches, investing in a San Martin timepiece is a decision you won’t regret. With the power of CNC machining behind their production processes, each watch promises precision, elegance, and a lasting legacy.

“`

Links:

Parceiros:

In the realm of luxury watches, San Martin has established a name synonymous with precision and quality. The production of their watch cases using CNC machining is pivotal in achieving the detailed craftsmanship that the brand is known for. CNC machining allows for intricate designs, high accuracy, and efficient production processes. This technology not only enhances the durability and aesthetic of the watch cases but also ensures that each piece meets rigorous standards. As a potential buyer, investing in a San Martin watch means owning a timepiece crafted with the utmost care and modern techniques, promising longevity and style.

FAQ

What is CNC machining?

CNC machining stands for Computer Numerical Control machining, a process used to automate machine tools through computer programming. It is widely used in manufacturing for producing precise parts, such as watch cases, with high repeatability and accuracy. This method enables intricate designs that traditional methods cannot achieve.

How does CNC machining benefit San Martin watch cases?

CNC machining offers several benefits for San Martin watch cases, including precise dimensions, consistency in quality, and the ability to create complex designs. This technology enhances the overall aesthetic appeal and durability of the watch, ensuring that each piece is meticulously crafted to meet luxury standards.

Is CNC machining more expensive than traditional methods?

While CNC machining often requires a higher initial investment due to the technology and machinery involved, it can lead to cost savings in the long run. The efficiency, precision, and reduced material waste associated with CNC machining make it a valuable investment in high-quality production.

Can custom designs be made using CNC machining?

Yes, CNC machining is highly adaptable, allowing for custom designs to be easily produced. San Martin can create unique watch cases that reflect individual tastes and preferences, making it possible for customers to own one-of-a-kind timepieces.

How does CNC machining enhance the durability of watch cases?

CNC machining enhances the durability of watch cases by creating parts from solid materials with precise fittings. This process reduces the risk of weak points, ensuring that the watch is resistant to wear, corrosion, and impacts. As a result, San Martin watches are built to last, combining beauty with resilience.

Conclusion

In conclusion, CNC machining plays a crucial role in the production of San Martin watch cases, merging modern technology with traditional craftsmanship. By choosing San Martin, you are not only investing in a timepiece that embodies precision and style, but also ensuring a durable and high-quality product that stands the test of time. Discover the exceptional collection today and experience the blend of innovation and elegance.