What is CAD render influence on San Martin Watch production?

If you are a watch enthusiast or someone interested in the intricate world of horology, you might have heard about Computer-Aided Design (CAD) rendering. This innovative technology plays a critical role in the production of high-end watches, including the exquisite timepieces from San Martin. In this article, we will explore what CAD rendering is, its influence on San Martin watch production, and how it enhances the design, functionality, and overall quality of these remarkable watches.

Understanding CAD Rendering

Computer-Aided Design (CAD) rendering is a sophisticated process that uses computer software to create precise digital drawings and simulations of products. In the realm of watchmaking, CAD rendering allows manufacturers to develop detailed models that showcase every aspect of their designs. This digital visualization can be an advantage in various stages of production:

- Concept Development: Designers can quickly transform their ideas into visual representations.

- Material Selection: CAD software enables detailed simulations of materials, helping determine the most suitable options.

- Prototyping: Digital models can be converted into prototypes, saving time and resources.

- Marketing: Stunning visualizations can be used to promote watches even before they are physically made.

The Influence of CAD Rendering on San Martin Watch Production

Precision and Accuracy

One of the most significant influences of CAD rendering on San Martin watch production is the precision and accuracy it offers. Traditional watch design methods involve hand-drawn sketches, which can oftentimes lead to discrepancies in dimensions. However, with CAD, every measurement can be inputted and adjusted digitally to ensure that every component fits together perfectly. This level of accuracy is crucial in fine watchmaking, where even minute errors can affect performance and aesthetics.

Streamlined Design Process

Gone are the days when designers spent countless hours sketching and redrafting designs. The CAD rendering process vastly streamlines the design cycle for San Martin watches. Designers can quickly create and modify 3D models, enabling more flexibility and creativity during development. This agile approach not only enhances the final product but also reduces time-to-market, allowing San Martin to introduce new models more rapidly and efficiently.

Enhanced Aesthetic Appeal

Another vital aspect of CAD rendering is its ability to create high-quality visuals that can represent different design concepts. San Martin uses this technology to explore various color combinations, textures, and finishes, allowing designers to visualize how a watch will look from multiple angles before production begins. The ability to experiment with these visual elements helps in crafting timepieces that are not just functional, but also visually striking.

Material Simulation

Material choice is critical in watchmaking, as the selected materials impact not only the watch’s durability but also its overall aesthetics. CAD software allows San Martin to simulate how different materials will look and perform in real-world conditions. For instance, the rendering process can show how various metals reflect light, or how certain finishes will endure wearing over time. This capability enables the brand to make informed decisions about material selection, ensuring high-quality products that meet their standards and customer expectations.

Collaboration Across Teams

The modern watch design process involves multiple teams, including designers, engineers, and marketers. CAD rendering simplifies collaboration across these teams by providing a single digital model that can be shared and modified. Changes made by one team can be instantly reflected in the model, improving communication and reducing the chances of errors. San Martin’s seamless collaboration leads to a more cohesive design and production process, ultimately resulting in higher-quality watches.

Prototyping and Testing

With the ability to create accurate 3D models, San Martin can produce prototypes more efficiently than traditional methods would allow. These prototypes can be rigorously tested for functionality, design, and comfort before going into full production. This step is essential to ensure that the watches not only look good but also perform exceptionally well. By investing in prototyping, San Martin minimizes the risk of design flaws or performance issues in the final product.

The Benefits of CAD Rendering for Customers

The influence of CAD rendering on San Martin watch production extends beyond design and manufacturing. It significantly enhances the customer experience in various ways:

- Confidence in Quality: Knowing that advanced technology is used in the design and production process instills confidence in potential buyers regarding the quality and craftsmanship of San Martin watches.

- Innovative Design: Customers can expect innovative and captivating designs that are a product of rigorous development and testing using CAD technology.

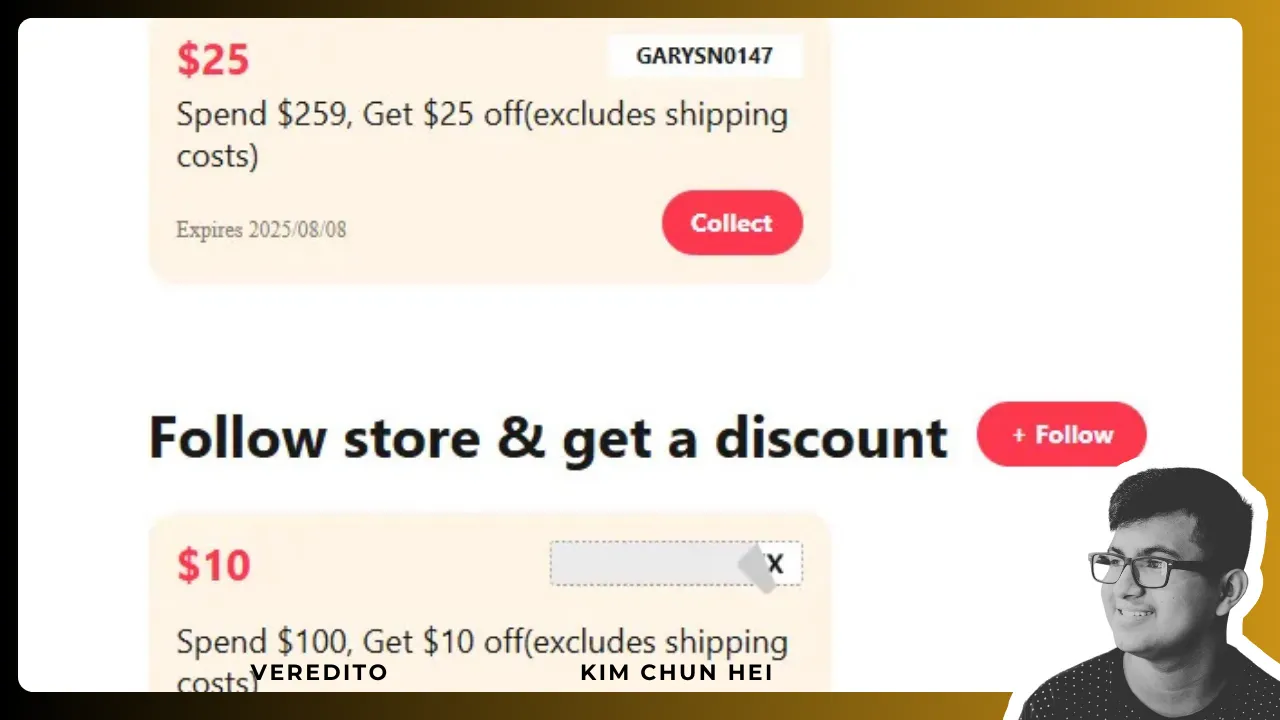

- Tailored Options: With CAD rendering, there is potential for customization, allowing customers to choose features that best suit their personal style and preferences.

The Future of CAD Rendering in Watchmaking

As technology continues to evolve, so does the potential for CAD rendering in watchmaking. The future may hold even more innovative capabilities such as:

- Incorporation of Augmented Reality: Customers may soon be able to virtually “try on” watches using augmented reality apps, thanks to advanced CAD models.

- AI-Driven Design: Artificial Intelligence can analyze trends and customer preferences to help create more desirable watch designs.

- Eco-Friendly Materials: CAD could facilitate the exploration of sustainable materials, aligning with the growing demand for environmentally conscious products.

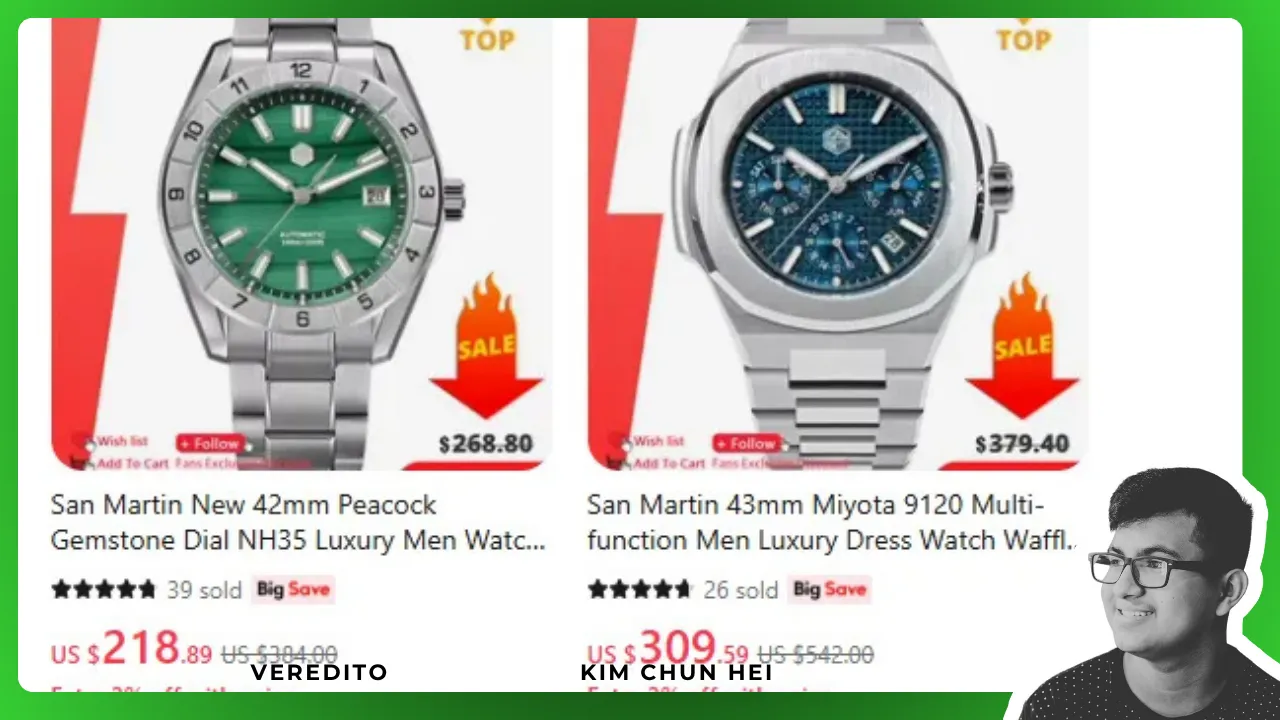

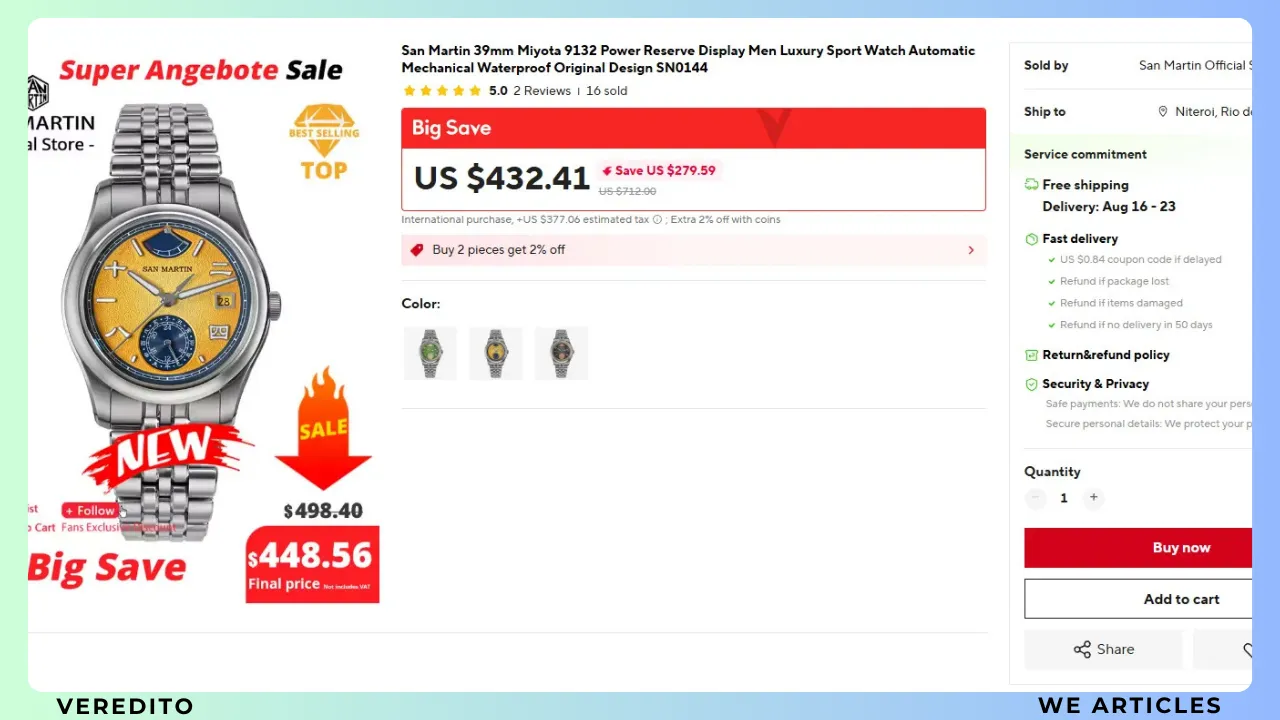

Investing in a San Martin Watch

If you are considering a new watch purchase, investing in a San Martin watch means choosing a product that benefits from the advanced capabilities of CAD rendering. With a focus on precision, aesthetics, and quality, each watch is engineered to provide timeless elegance and durability. San Martin watches not only reflect craftsmanship but also incorporate cutting-edge technology, making them a valuable addition to any watch collection.

Conclusion

In summary, CAD rendering has a profound influence on the production of San Martin watches. This technology enhances every stage of the design and manufacturing process, from initial concept to the final product. As CAD continues to evolve, so too will the possibilities for watchmakers, allowing them to bring even more exceptional timepieces to the market. Investing in a San Martin watch means choosing not just a timepiece, but a symbol of innovation, quality, and style.

Links:

Parceiros:

In the production of San Martin Watches, CAD render technology plays a pivotal role in elevating design precision and enhancing the overall manufacturing process. By utilizing Computer-Aided Design (CAD) rendering, San Martin can visualize intricate designs with unmatched clarity, allowing for meticulous adjustments before physical production. This innovative approach not only streamlines fabrication but also significantly reduces errors, ensuring that each watch meets the brand’s high-quality standards. Moreover, CAD rendering fosters creativity, enabling designers to experiment with various styles and features without the constraints of traditional methods. With these advantages, investing in a San Martin Watch guarantees a blend of sophistication, reliability, and cutting-edge technology.

Frequently Asked Questions

What is CAD rendering, and how does it benefit watch production?

CAD rendering is a digital design process that allows for the creation of detailed 3D representations of products. In watch production, it helps designers visualize designs accurately, make informed adjustments, and streamline manufacturing. This reduces costs and improves product quality.

How does San Martin utilize CAD technology?

San Martin employs CAD technology to create precise designs for their watches, allowing for detailed visualizations and adjustments before production. This ensures that every aspect of the watch meets their exacting standards, enhancing both aesthetics and functionality.

What are the advantages of using CAD in watch design?

- Increased design accuracy

- Reduced production errors

- Faster prototyping

- Enhanced creative possibilities

- Cost-effective manufacturing

Does CAD rendering improve the customer experience?

Yes, CAD rendering improves the customer experience by ensuring that the final product closely matches the envisioned design. This leads to higher satisfaction as buyers receive a watch that reflects the quality and detail promised by San Martin.

Can CAD technology influence the price of San Martin Watches?

While implementing CAD technology can increase initial development costs, it ultimately leads to more efficient production and better quality control. This means that customers receive a superior product, often justifying the pricing without compromising on luxury and craftsmanship.