What is dial finishing process in San Martin Watch production?

What is the Dial Finishing Process in San Martin Watch Production?

The world of luxury watches is filled with intricate craftsmanship, precision engineering, and a rich history of tradition. Among the many esteemed brands, San Martin is recognized for its dedication to quality and fine details. One of the critical steps in watch production that significantly contributes to the overall aesthetic and functionality of a timepiece is the dial finishing process. This process not only enhances the beauty of the watch but also plays a vital role in its performance and longevity.

Understanding the Dial Finishing Process

The dial finishing process involves a series of meticulous steps aimed at producing the watch dial, the face of the watch where time is displayed. This process is essential, as the dial serves not just as a functional element but also as a design statement. The process can be broken down into various stages:

1. Material Selection

The first step in the dial finishing process is the selection of high-quality materials. San Martin often uses materials such as:

- Brass: A popular choice for its durability and ability to hold finishes well.

- Stainless Steel: Used for its resistance to corrosion and strength.

- Enamel: Favored for its beauty and resistance to wear.

- Carbon Fiber: Provides a modern, sporty touch while being lightweight and strong.

The choice of material not only affects the watch’s appearance but also its weight and durability, making this decision fundamental in the production of San Martin watches.

2. Dial Cutting and Shaping

Once the material is selected, the next step involves cutting and shaping the dial. This process requires precision machining to ensure that the dial is accurate in size and shape. Advanced CNC (Computer Numerical Control) machines are often employed to achieve this high level of precision.

3. Surface Treatment

After cutting, the surface of the dial undergoes treatment to prepare it for finishing. This step may involve:

- Sanding: To create a smooth surface and remove any imperfections.

- Polishing: Enhances the finish and adds shine, giving the dial a high-quality look.

- Coating: Application of protective coatings to enhance durability and resistance to scratches.

Each of these steps is critical in ensuring that the final product meets the high standards associated with the San Martin brand.

4. Applying Finishing Techniques

With the surface prepared, various finishing techniques are then applied to add character and complexity to the dial. Some popular finishing techniques include:

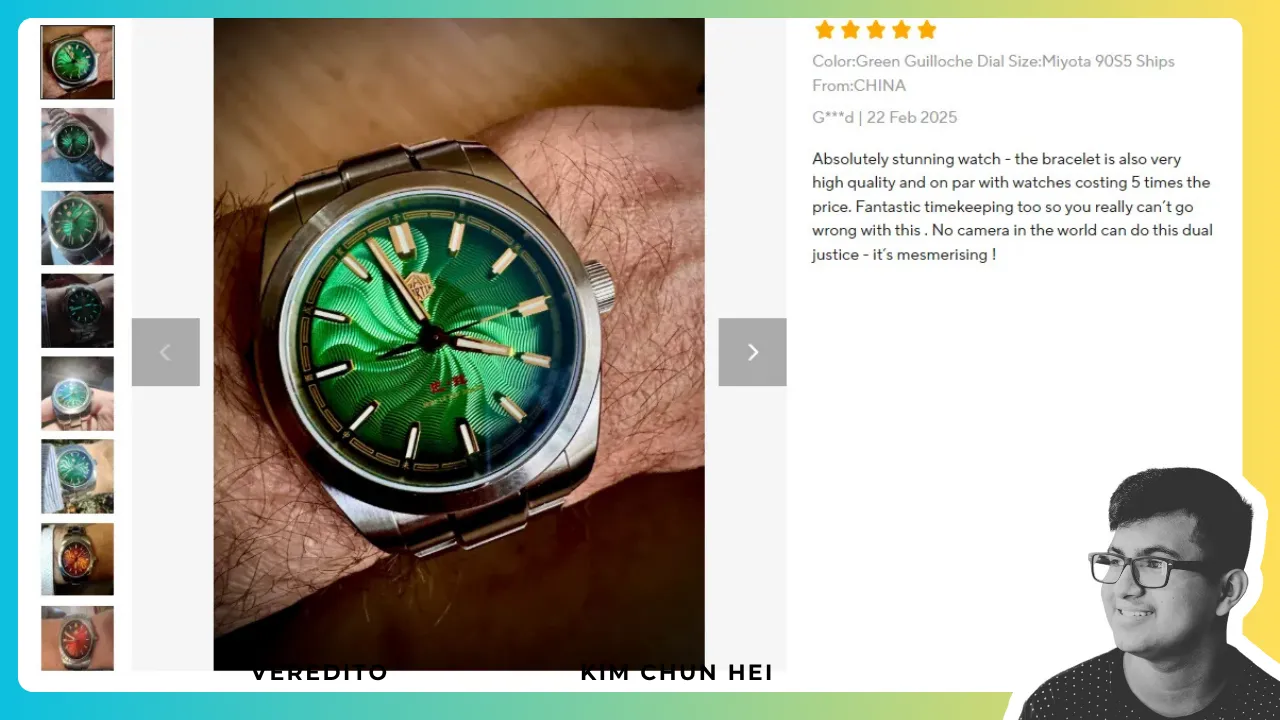

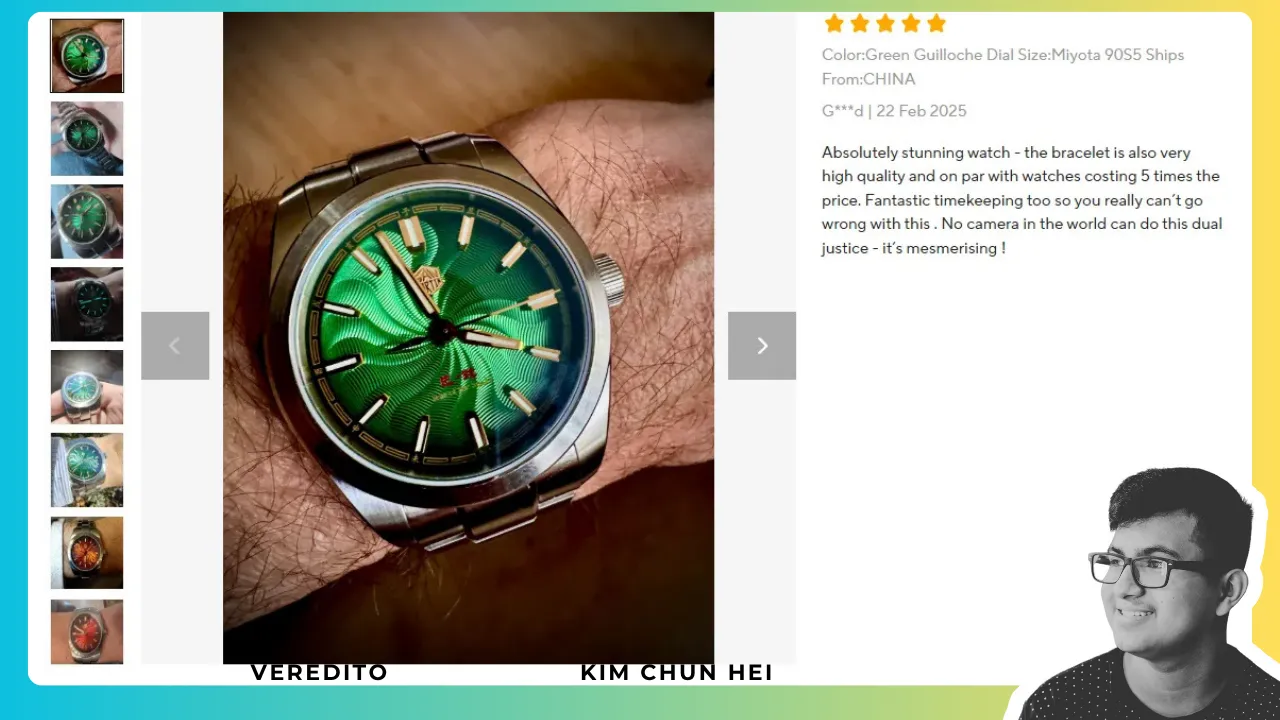

- Sunburst Finish: Creates a stunning effect as light interacts with the dial surface, producing a radiant appearance.

- Matte Finish: Offers a subtle, sophisticated look that reduces glare and reflections.

- Brushed Finish: Provides a textured appearance, enhancing grip and aesthetic appeal.

- Lacquering: Adds a layer of color and depth, often used in more vibrant designs.

Each finishing technique carries its own charm and style, catering to diverse consumer preferences, making it an essential aspect of the dial finishing process.

5. Dial Markings and Indicators

The next crucial step in the finishing process is the addition of markings and indicators. This includes:

- Hour Markers: Essential for time-telling, these can be simple dots or intricate designs.

- Brand Logo: Typically placed prominently to assert the identity of the watch.

- Sub-dials and Complications: In the case of watches with features like chronographs, additional markings are added for functionality.

The precision and placement of these elements are paramount, as they not only ensure legibility but also enhance the overall aesthetic appeal of the watch.

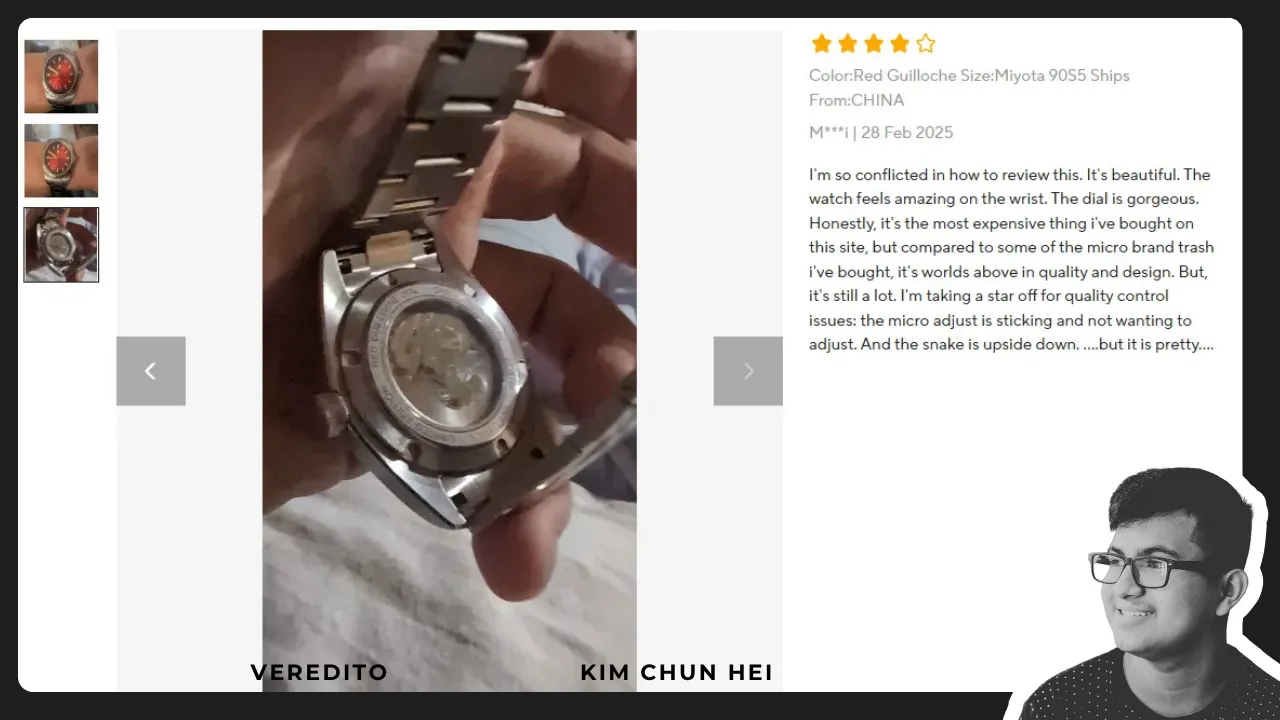

6. Quality Control

Once all aspects of the dial are complete, rigorous quality control checks are conducted. This includes:

- Visual Inspection: Checking for any imperfections in the finish and markings.

- Dimensional Measurement: Ensure that the dial fits perfectly within the watch case.

- Functional Testing: Verifying that all markers are correctly aligned and visible.

These quality checks are crucial in maintaining the high standards that San Martin watches are known for.

The Importance of the Dial Finishing Process

The dial finishing process is not merely a cosmetic aspect of watchmaking. It plays a pivotal role in the overall functionality, quality, and perception of the watch. Here are some key reasons why this process is vital:

- Aesthetic Appeal: A well-finished dial enhances the visual attractiveness of the watch, making it more desirable to consumers.

- Brand Identity: The dial is often the most visible part of a watch; its design can embody the brand’s philosophy and heritage.

- Durability: Proper finishing techniques contribute to the watch’s ability to withstand wear and tear over time.

- Legibility: A thoughtfully designed dial allows for easy readability, which is essential in the functionality of the watch.

Investing in a San Martin Watch

Choosing to invest in a San Martin watch is not merely a purchase; it is an acquisition of a piece of art meticulously crafted with attention to detail. The dial finishing process ensures that each watch is not only stylish but functional and reliable. Here are several reasons why investing in a San Martin watch is a wise decision:

- Exceptional Craftsmanship: Each timepiece is crafted by skilled artisans who take pride in their work, ensuring top-notch quality.

- Value for Money: San Martin offers luxury quality at competitive prices, making it accessible for those who appreciate fine watches without breaking the bank.

- Variety of Designs: From classic to modern styles, there is a San Martin watch to suit every taste and occasion.

- Longevity: With their durable construction and quality materials, San Martin watches are designed to last for years, becoming a cherished part of your collection.

Incorporating a San Martin watch into your collection not only elevates your personal style but also signifies a commitment to quality and craftsmanship. The exquisite attention to detail found in the dial finishing process ensures that your timepiece is as unique as the moments it helps you capture.

Conclusion: Elevate Your Collection with San Martin

In the realm of fine watches, every detail matters, and the dial finishing process is a testament to the quality and craftsmanship that San Martin embodies. By choosing a San Martin watch, you are investing in a piece of horological art that reflects both style and substance. With its impeccable finishes, durable materials, and precise craftsmanship, a San Martin timepiece is sure to become a treasured asset in your collection.

Explore the beauty of San Martin watches today and find the ideal timepiece that resonates with your unique taste and lifestyle.

Links:

Parceiros:

The dial finishing process in San Martin watch production is crucial for ensuring the aesthetic appeal and precision of each timepiece. This meticulous process involves various techniques such as polishing, engraving, and applying luminous materials. The attention to detail not only enhances the visual attractiveness but also contributes to the watch’s functionality. San Martin’s commitment to quality means that each dial is crafted with precision, resulting in a product that stands out. Investing in a San Martin watch means enjoying a blend of artistry and durability, making it a perfect companion for any occasion.

FAQ

What techniques are used in the dial finishing process?

The dial finishing process at San Martin involves techniques such as polishing, engraving, and the application of luminous materials. Each of these steps ensures that the dial is not only beautiful but also enhances visibility in low light conditions.

How does the dial finishing affect the watch’s performance?

The dial finishing process significantly impacts the watch’s performance by ensuring that all markers and elements are accurately placed and easy to read. A well-finished dial enhances the overall functionality of the watch, providing users with reliable timekeeping.

Are San Martin dials customizable?

Yes, San Martin offers various customization options for dials, allowing customers to choose features like color, markers, and finishes. This customization ensures that each watch can reflect the owner’s personal style.

What materials are used in the dial finishing process?

San Martin utilizes high-quality materials like stainless steel, ceramic, and minerals in the dial finishing process. These materials are carefully selected to ensure durability and an attractive finish that holds up over time.

How long does the dial finishing process take?

The dial finishing process can take anywhere from a few days to several weeks, depending on the complexity and customization of the design. Quality control is essential, and each dial undergoes thorough inspection before it reaches the market.

Conclusion

In summary, the dial finishing process in San Martin watch production plays a pivotal role in ensuring both beauty and functionality. With an array of techniques and high-quality materials, San Martin watches are crafted to last while appealing to various styles. Choosing a San Martin watch not only signifies a purchase but an investment in craftsmanship and precision that you can enjoy for years to come.